Blog Category: Harvest

Harvesting More Acres Per Day: Does Your Concave Speed Up Your Operation?

When harvest hits full stride, the biggest advantage isn’t always horsepower, header width, or who starts before sunrise, it’s how efficiently your combine threshes. The faster you can separate grain cleanly and consistently without stopping for resets, clogging, rotor loss, or part changes, the more acres you finish before weather, moisture, or breakdowns cut your plans short.

» Read more about: Harvesting More Acres Per Day: Does Your Concave Speed Up Your Operation? »

Upgrading Your Combine? Don’t Overlook Your Concaves

Every season, technology pushes modern combines to new levels of productivity, bigger engines, smarter automation, greater capacity, and faster harvesting speeds. It’s no surprise many farmers invest heavily in new machines, expecting immediate performance gains, smoother operation, and reduced grain loss. But here’s the truth that often goes unnoticed: a combine is only as good as the concaves inside it.

» Read more about: Upgrading Your Combine? Don’t Overlook Your Concaves »

When you invest in harvest equipment, you’re not just buying parts, you’re buying uptime, efficiency, and peace of mind. The i-paddock Typhoon drum was engineered with exactly that philosophy: eliminate bottlenecks, increase capacity, and keep you running through the toughest crop conditions. But one of the most common questions farmers ask is: How long will the Typhoon last?

Duck Foot Paddle Tines: What’s the Installation Process Like?

A Quick Upgrade Farmers Can Install Without Losing Harvest Time.

When harvest is rolling, every minute is worth money. Nobody wants to shut a header down, drag out tools, and lose daylight just to install aftermarket parts. That’s why one of the first questions farmers ask about Duck Foot Paddle Tines is simple:

“How long will it take to put them on?”

» Read more about: Duck Foot Paddle Tines: What’s the Installation Process Like? »

Can Your Concaves Handle High-Moisture Crops? Here’s Why It Matters

Wet crops slow harvest. Sticky stems, damp pods, tough green spots, they all do the same thing: plug the rotor, pack the concaves, and force you to slow down. When moisture shows up, most concaves start fighting instead of feeding.

» Read more about: Can Your Concaves Handle High-Moisture Crops? Here’s Why It Matters »

How Do Duck Foot Tines Impact Fuel Efficiency?

Fuel is one of the biggest costs of harvest. Every hour in the field burns money, and every acre that takes longer than it should adds up fast. While most farmers think fuel savings come from engine tuning or running fewer passes, one of the simplest ways to cut fuel use starts at the header.

» Read more about: How Do Duck Foot Tines Impact Fuel Efficiency? »

The Biggest Mistakes Farmers Make With Their Concaves (And How to Avoid Them)

When harvest hits full stride, concaves are the last thing most farmers want to think about, until something goes wrong. Plugging, rotor rumble, cracked grain, and poor separation are often blamed on the crop or the combine, when in reality, the real culprit is sitting right under the rotor. Here are the most common concave-related mistakes growers make (and how the Razors Edge system eliminates them).

» Read more about: The Biggest Mistakes Farmers Make With Their Concaves (And How to Avoid Them) »

When you’re running a mixed operation, you need equipment that handles whatever you put in front of it. The i-paddock Typhoon drum was built exactly for that, consistent feeding, aggressive grab, and smooth, even flow through the combine. While it performs in almost any crop, farmers see the biggest benefits in canola, soybeans, lupins, and barley.

» Read more about: What Crops Is the Typhoon Best Suited For? »

How Accurate Is the ScherGain System for Measuring Grain Loss?

When you check grain loss, you need real numbers, not guesses. Looking at the ground behind the combine or kicking through chaff won’t tell you how many bushels you’re leaving in the field. The ScherGain Drop Pan System does.

» Read more about: How Accurate Is the ScherGain System for Measuring Grain Loss? »

What is the KAS Pre-Cleaner? The Simple Upgrade That Protects Engines, Cuts Costs, and Keeps You Running

Dust always wins. It plugs filters, cuts horsepower, burns more fuel, and shuts machines down at the worst possible time. Whether you’re running a combine, tractor, skid steer, or industrial equipment, dirty air is one of the quietest profit-killers on the farm.

You hit a patch of green or damp crop and suddenly the header starts to fight you. Material bunches, wraps, or plugs, and the combine slows to a crawl. These are the moments that separate an average feeding drum from one built to handle tough conditions. The Typhoon is the feeding drum for green or damp crops.

» Read more about: How Does the Typhoon Handle Green or Wet Crops? »

Does Ground Speed Change Between Sizes of Headers?

Not always. Many operators wonder, does header size affect ground speed, but moving up to a bigger header doesn’t mean you have to crawl. In reality, your ground speed has far more to do with what’s coming through the machine than how wide your header is.

» Read more about: Does Ground Speed Change Between Sizes of Headers? »

How Long Will My KAS Filter Last?

The KAS Pre-Cleaner is one of those upgrades that pays for itself faster than you expect, and the KAS pre cleaner benefits show up almost immediately. It mounts to your machine’s air intake and spins out debris before it ever reaches your main air filter. That means less restriction, cleaner air to your engine, and far fewer filter changes. It’s a simple, effective way to extend service intervals and keep you running.

Unlike a basic pre-screen,

Razors Edge Concaves: What Farmers Are Saying

When you upgrade to Razors Edge Concaves, you’re not just swapping out parts, you’re rethinking how your combine handles crop. The design is built to reduce rotor loss, clean up your sample, and make your life easier across multiple crops, all without cover plates.

» Read more about: Razors Edge Concaves: What Farmers Are Saying »

When it comes to harvest gear, durability isn’t a nice-to-have, it’s nonnegotiable. The Typhoon Feed Drum was built by an Australian farmer who was sick of fixing parts when we should’ve been harvesting. So he designed a feed drum that lasts.

Are Duck Foot Paddle Tines Compatible with My Header?

If you’re thinking about running Duck Foot Paddle Tines, the first question is: Will they fit your header? The short answer? Most likely, but it’s worth checking a few simple things before you place an order.

» Read more about: Are Duck Foot Paddle Tines Compatible with My Header? »

Why the KAS Pre-Cleaner Is a Must-Have for Skid Steers, Tractors & Combines

Keeping machines running in dusty, high-debris environments has always been a challenge. That’s where the Redekop KAS Pre-Cleaner comes in. It’s a smart, simple upgrade designed to protect your engine and reduce the number of air filter changes throughout the season. Built for combines, skid steers, tractors, and more, it’s an easy win for better uptime and longer machine life.

» Read more about: Why the KAS Pre-Cleaner Is a Must-Have for Skid Steers, Tractors & Combines »

ScherGain Drop Pan Lifespan and Acres

The ScherGain Drop Pan is a magnet mounted, remote-release tool that attaches under your combine to measure harvest loss. Drop it under your load, clean the sample, measure it with the grain gauge, and use the chart to convert kernels into loss per acre. It works as a calibration tool, not a wear part like knives or bars. Because of that, the ScherGain drop pan lifespan stretches across multiple harvests and seasons. It gives farmers a long-lasting,

How to Set Your Combine for Maximum Efficiency with Razors Edge Concaves

Running Razors Edge Concaves isn’t about bolting them in and hoping for the best. These concaves are designed to thresh efficently up front and distribute crop evenly through the rotor. However, to get the return you expect, you need to set the machine up correctly. This guide walks through how to get things dialed in, step by step.

» Read more about: How to Set Your Combine for Maximum Efficiency with Razors Edge Concaves »

What Crops Will Duck Foot Tines Work In

Duck Foot Tines Work Well With Most Crops.

Duck Foot Tines improve harvest efficiency in both thin crops like soybeans and in larger, heavier crops such as cereals and pulses. By lifting and feeding crops more consistently, they save bushels that would otherwise be lost at the header.

» Read more about: What Crops Will Duck Foot Tines Work In »

The Typhoon drum’s patented paddle flighting and aggressive finger design deliver exceptional Typhoon drum feeding performance, keeping crops moving in a continuous, even stream. By smoothing feed into the feederhouse, operators can maintain higher ground speeds with fewer slowdowns. In canola and legumes, that feeding performance often translates into a gain of 2 to 4 kilometers per hour when conditions allow.

Why speed goes up

Ground speed is limited by how steadily the header and feederhouse can deliver the crop.

» Read more about: Does the Typhoon Really Help Me Harvest Faster? »

Will the ScherGain Drop Pan Work on Any Combine?

The ScherGain Drop Pan works on most major makes and models. On four-wheel drive or rear-wheel assist machines, mount the pan farther forward so the rear axle doesn’t interfere with the drop.

» Read more about: Will the ScherGain Drop Pan Work on Any Combine? »

One Concave, All Conditions: The One Harvesting Upgrade You’ve Been Waiting For

Simplify harvest with universal combine concaves for all crops and conditions, eliminating downtime and constant setup changes.

» Read more about: One Concave, All Conditions: The One Harvesting Upgrade You’ve Been Waiting For »

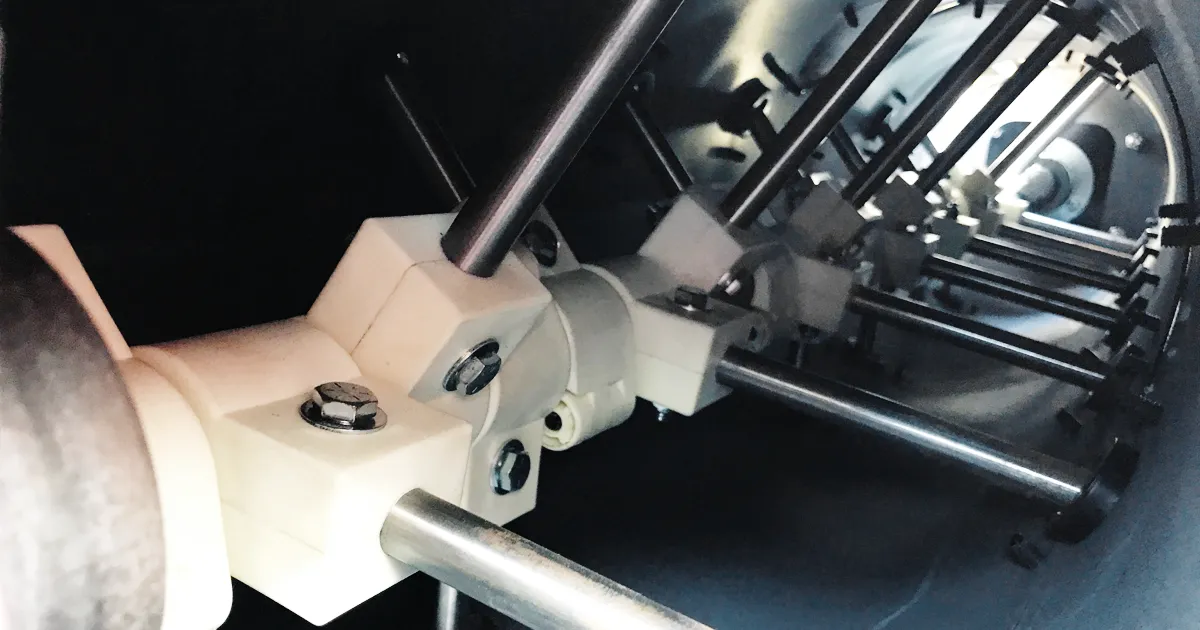

When it comes to feeding performance, not all drums are created equal. Most lock you into a single finger position with no real way to adjust for different crops or conditions. That’s where the Typhoon feeder drum breaks the mold.

» Read more about: How the Typhoon’s Quick-Adjust Feature Gives You Total Feeding Control »

Don’t Let Cracked Beans and Rotor Loss Hurt Your Bottom Line

Every cracked grain and every kernel lost out the back of the combine is money left in the field. For growers running high-value crops like soybeans or edible beans, even small losses add up quickly.

» Read more about: Don’t Let Cracked Beans and Rotor Loss Hurt Your Bottom Line »

Reel Pitch Matters: Getting the Most from Your Duck Foot Paddle Tines

Installing Duck Foot Paddle Tines is one of the easiest ways to improve crop feeding across your header, but to unlock their full performance, reel settings matter. One question we often get is: Do I need to adjust my reel pitch after installing the paddles? The short answer? Yes, and here’s why.

» Read more about: Reel Pitch Matters: Getting the Most from Your Duck Foot Paddle Tines »

If you’re looking at the i-paddock Typhoon to boost your spreading performance, one of the first questions that probably comes to mind is: is the Typhoon compatible with my header? You’re not alone, compatibility is one of the most common questions we get from farmers across North America.

The good news? We built the Typhoon with compatibility in mind, especially for the headers that farmers rely on most.

» Read more about: Is the Typhoon Compatible With My Header? »

Power That Lasts: Understanding Battery Life on the ScherGain Drop Pan

When it comes to testing for combine loss, the last thing you need is to fight with unreliable batteries. The ScherGain Drop Pan Solution System is built to make harvest testing fast, accurate, and headache-free, and that includes the power source behind it. Let’s talk the ScherGain Drop Pan battery life, maintenance, and what you can expect from the lithium-ion battery that runs your drop pan.

» Read more about: Power That Lasts: Understanding Battery Life on the ScherGain Drop Pan »

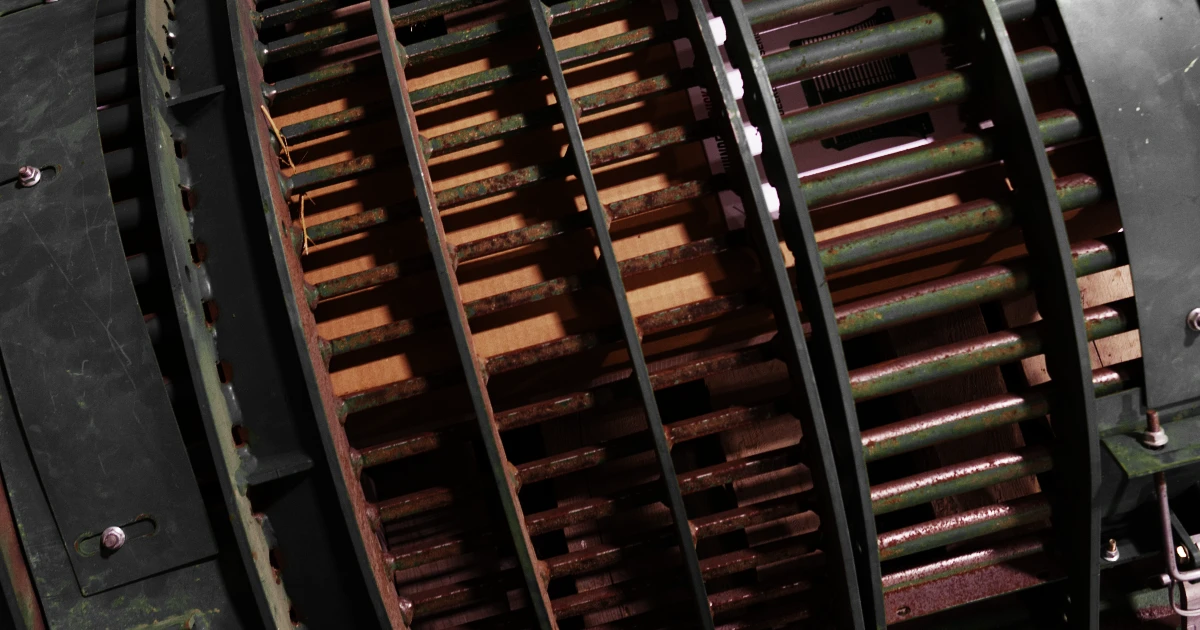

The Science Behind Better Threshing: How Razors Edge Concaves Work

When it comes to your combine’s performance, threshing and separation are everything. Miss the mark on either, and you’re leaving grain in the field or cracking what you do manage to collect. That’s why concave design matters more than most realize.

» Read more about: The Science Behind Better Threshing: How Razors Edge Concaves Work »

If you’ve ever fought with uneven crop flow or frustrating feed delays during harvest, chances are your OEM drum is part of the problem. Factory-standard finger drums often don’t cut it, especially in tough conditions or when you’re pushing hard to beat the weather. You need a combine drum upgrade for better crop feeding.

» Read more about: More Fingers, Better Feed: What Makes the Typhoon Stand Out »

Why Your Current Concaves Are Holding You Back (And What to Do About It)

If you’ve ever felt like your combine should be doing more—threshing cleaner, holding grain better, running smoother, you’re probably right. The problem may not be your combine at all; it could be you need a combine concave upgrade for higher yield

Whether you’re running OEM concaves that came standard or an aftermarket setup that hasn’t lived up to the promise, there’s a good chance your current system is holding back your harvest potential.

» Read more about: Why Your Current Concaves Are Holding You Back (And What to Do About It) »

When (and When Not) to Use Duck Foot Paddle Tines

Duck Foot Paddle Tines have made a name for themselves by helping farmers move more crop off the header and into the combine. Whether you’re dealing with short crops, brittle pods, or tough harvest conditions, they’re a simple upgrade that delivers real results.

» Read more about: When (and When Not) to Use Duck Foot Paddle Tines »

When it comes to upgrading your harvest performance, downtime is the last thing you want. That’s why the i-paddock Typhoon is designed with simplicity and speed in mind—so you can get it installed and back in the field without losing a valuable harvest window.

» Read more about: Fast & Simple: Installing the i-paddock Typhoon »

Why Am I Throwing So Much Grain Out the Back?

If you’ve ever looked behind your combine and seen grain scattered on the ground, you’re probably asking yourself, “Why am I throwing so much grain out the back?” The answer, more often than not, comes down to one main factor: your harvesting speed.

» Read more about: Why Am I Throwing So Much Grain Out the Back? »

Mastering Grain Loss Reduction: Dialing In Your Combine for a Perfect Harvest

Harvest season is a make-or-break time for every farmer. With all the work that goes into growing, managing, and finally harvesting crops, every bushel lost can feel like a small tragedy. Yet, many farmers unknowingly let valuable grain slip away due to improper combine settings. This post will walk you through everything you need to know about identifying, diagnosing, and correcting grain loss in your combine. Whether you’re a seasoned operator or new to the game,

» Read more about: Mastering Grain Loss Reduction: Dialing In Your Combine for a Perfect Harvest »

What Makes Duck Foot Paddle Tines Different?

When harvest starts, every piece of equipment on your combine needs to do its job—and do it right. Header loss, crop flow problems, and unnecessary wear on your machine can add up fast. That’s why choosing the right attachments matters. If you’re looking for something that genuinely improves harvest performance, Duck Foot Paddle Tines bring something different to the table.

Here’s what sets them apart.

» Read more about: What Makes Duck Foot Paddle Tines Different? »

When you’re in the thick of harvest, everything comes down to how efficiently your machine can move crop through the front. Slowdowns, blockages, and slugging don’t just cost time—they cost yield. That’s why even small design changes, like drum diameter, can make a massive difference.

» Read more about: How a Smaller Diameter Drum Improves Harvest Flow »

Ag in Motion innovation awards showcase top 2025 ag technology

The Innovation Program Awards recognized top innovators in Canadian agriculture and technology ahead of the opening of Ag in Motion 2025. Read the full story on producer.com

The Monday night ceremony at Saskatchewan Polytechnic campus in Saskatoon celebrated winners across five categories: agronomics, agtech, business solutions, environmental sustainability and equipment.

» Read more about: Ag in Motion innovation awards showcase top 2025 ag technology »

Thunderstruck Ag Launches Razors Edge Concaves for Versatile, High-Efficiency Harvesting

Thunderstruck Ag has officially launched Razors Edge Concaves, a new threshing solution designed to handle multiple crops with a single setup. The system addresses common farmer concerns such as equipment wear, yield loss, and the complexity of changing parts between crops. Razors Edge Concaves were developed with a focus on efficiency and adaptability in high-pressure harvesting environments. Read the full story on igrownews.com

How Does the Variable Spacing on the Razors Edge Concaves Work?

When you’re pushing your combine hard during harvest, efficiency is everything. The Razors Edge Concaves by Thunderstruck Ag Equipment offer a smart solution to boost your threshing performance through variable spacing technology. This innovative feature plays a key role in optimizing how well your combine separates crops, delivering better results with less effort. Let’s explore how the variable spacing system works and why it matters for your harvest.

» Read more about: How Does the Variable Spacing on the Razors Edge Concaves Work? »

It’s a good question—and one we hear often: “If the i-paddock Typhoon doesn’t have a reversing clutch, how do I back it out when it plugs?”

The answer? You reverse it just like you would any OEM header drum—using your combine’s standard reversing procedure. No special tools, no unique setup. It’s that simple.

» Read more about: How Do You Reverse the Typhoon Without a Reversing Clutch? »

Multi-Crop Harvesting Made Easy: The Concave That Does It All

If you’re harvesting multiple crops in a season, you know the drill: what works great in wheat might struggle in soybeans. What flows clean in canola could plug up in corn. Every crop change usually means climbing into the machine to swap cover plates, change settings, or wrestle with worn components.

But what if you didn’t have to?

» Read more about: Multi-Crop Harvesting Made Easy: The Concave That Does It All »

How Long Will Duck Foot Paddle Tines Actually Last?

It’s one of the first questions farmers ask before making a change: “How many acres am I going to get out of these?”

Fair question. When you’re investing in a product like Duck Foot Paddle Tines, you’re not just looking for a better harvest—you’re looking for something that’ll hold up, season after season, without needing to be constantly replaced.

Here’s the honest answer: more than 35,000 acres. And we’re not talking about babied,

» Read more about: How Long Will Duck Foot Paddle Tines Actually Last? »

The Real Cost of Grain Loss: Why Upgrading Your Concaves Pays Off

There’s a lot going on in the cab at harvest—monitoring yield, watching your ground speed, trying to beat the forecast. So when it comes to grain loss, it’s easy to rely on what the monitor says or assume what’s coming out the back is “normal.”

But here’s the thing: even a small amount of loss at the rotor or sieves adds up fast. And unless you’ve checked it with a pan, you might be leaving real money in the field without realizing it.

» Read more about: The Real Cost of Grain Loss: Why Upgrading Your Concaves Pays Off »

Why Am I Still Throwing Grain Out the Back? And What Do I Need to Change with My New Concaves?

If you’ve just upgraded to a set of Razors Edge Concaves, you’re already on the path to better threshing and reduced rotor loss. But if you’re still seeing grain hit the ground behind your combine, you’re not alone—and it doesn’t mean the concaves aren’t working. It usually means a few key settings need to be adjusted to match the new hardware.

“Do I Need Cover Plates for Tougher Crops?” Everything You Need to Know

One of the most common questions we hear from farmers is, “Do I need cover plates for tougher crops?” It’s a valid concern—traditional concaves often require cover plates to handle high-moisture corn, densely packed wheat, or other challenging conditions. But with Razors Edge Concaves, the answer is simple: No, you don’t.

» Read more about: “Do I Need Cover Plates for Tougher Crops?” Everything You Need to Know »

Cracks and Splits in Soybeans? Your Concave Could Be the Problem

If you’re noticing cracks and splits in your soybeans or edible beans, it’s time to take a closer look at your concave. While aggressive threshing might be effective for tougher crops like corn or wheat, it can be a major issue for delicate beans. The excessive force can damage the seed coat or split the beans entirely, leading to dockage at the elevator and cutting into your profits. Fortunately, Razors Edge Concaves offer a solution that protects your crop quality while maintaining harvest efficiency.

» Read more about: Cracks and Splits in Soybeans? Your Concave Could Be the Problem »

Let’s talk about the part of your harvest that might be holding you back.

If you’re dealing with uneven crop flow,, or frustrating blockages at the front of your header, you’re not alone. A lot of farmers wrestle with feeding issues—especially in bulky crops, short crops, or tough conditions. The good news? There’s a simple upgrade that can make a big difference.

» Read more about: How Can I Improve the Feeding of My Header? »

Why can’t I just use a couple Duck Foot Paddles?

It’s Like Running Half a Header

Imagine buying a new header, then only bolting on half the tines. Sounds a little crazy, right? That’s basically what happens when you try to run just a few Duck Foot Paddle Tines instead of installing a full set. You’re not giving the crop the even, consistent feed it needs across the entire header. And that inconsistency? It shows up fast.

» Read more about: Why can’t I just use a couple Duck Foot Paddles? »

Tired of Changing Concaves Mid-Season? Here’s the Solution

Ask any farmer who runs multiple crops through the same combine and you’ll hear it:

“I’m tired of swapping concaves.”

Whether it’s trying to get the settings just right for wheat after coming out of canola, or wrestling a set of cover plates to make soybeans clean up right after corn, the mid-season concave shuffle eats time, patience, and too often—profit.

» Read more about: Tired of Changing Concaves Mid-Season? Here’s the Solution »

You’re Losing Bushels — And You Don’t Even Know It

You’ve got the combine humming. The hopper’s filling fast. The grain cart is chasing you down the field, and the weather’s finally cooperating. Everything looks like it’s going right.

But there’s one big problem: You could be leaving money on the ground — and not even realize it.

» Read more about: You’re Losing Bushels — And You Don’t Even Know It »

How Uneven Sieve Loads Lead to Sieve Loss—And How to Fix It

If you’ve ever watched good grain go out the back of your combine, you know how frustrating sieve loss can be. But did you know that uneven sieve loads are often the root cause? When crop loads aren’t distributed evenly across the sieve, separation efficiency takes a hit, and valuable grain is lost. There’s a way to fix it.

» Read more about: How Uneven Sieve Loads Lead to Sieve Loss—And How to Fix It »

Don’t Settle for Less: Why Razors Edge Outperforms Estes XPR3 Concaves

Not all “all-crop” concaves are created equal. And when you’re in the middle of harvest, the difference between good enough and outstanding can be measured in lost bushels, missed hours, and dollars out of your pocket.

Both Estes XPR3 and Razors Edge Concaves claim to eliminate the need for cover plates, or mid-season swapping. But if you’re looking for the most complete, high-capacity, loss-reducing solution on the market; Razor’s Edge stands in a league of its own.

» Read more about: Don’t Settle for Less: Why Razors Edge Outperforms Estes XPR3 Concaves »

Thunderstruck’s Razors Edge Concaves

Founded in 2013, Thunderstruck Ag is a Canadian business that specializes in supplying cutting-edge agricultural solutions and equipment. The business began with a desire to sell unique products and soon integrated itself into the agricultural community, specifically targeting products designed by farmers for farmers. Read the full story at producer.com

What Makes Razors Edge Concaves Better Than What I already Have?

The Razors Edge Concaves by Thunderstruck Ag Equipment offer a significant leap forward in harvesting technology, delivering unparalleled efficiency, performance, and versatility. Designed with today’s farmer in mind, these concaves solve many of the common frustrations associated with traditional systems, particularly when it comes to handling multiple crops and managing threshing processes.

» Read more about: What Makes Razors Edge Concaves Better Than What I already Have? »

Solving Rotor Loss with Razors Edge Concaves: How the Right Concave Can Save Your Yield

In modern agriculture, every bushel of grain matters. Losing grain in the field is not only financially painful—it also reduces efficiency and can compromise the entire harvest season. Enter Razors Edge Concaves, a revolutionary solution designed to address rotor loss head-on. In this article, we’ll explore how Razors Edge Concaves tackle the problem of rotor loss, and why precision matters.

Unlocking Maximum Performance: Which Combines Work Best with the Razors Edge Concaves?

We know that farmers are always looking to boost their harvest efficiency and often ask if there are specific combine models that see better compatibility or performance. With the Razors Edge Concaves the good news is that they’re designed for broad compatibility, making them an ideal choice for a wide range of combine models.

Why Razors Edge Concaves Are Leading the Way in Reducing Rotor Loss and Increasing Grain Capture

When it comes to maximizing harvest efficiency, two critical factors to consider are reducing rotor loss and increasing grain capture. As you know, the ability to recover more grain and prevent loss directly impacts profitability, making concave selection a crucial decision. The Razors Edge Concaves have emerged as a top choice, outshining competitor products in these areas. Here’s how they stack up when it comes to reducing rotor loss and increasing grain capture.

Maximizing Combine Lifespan: How Razors Edge Concaves Reduce Stress and Last Longer

The Razors Edge Concaves stand out not only for their efficiency but also for their long-lasting durability. Designed with high-performance features like a hardened edge and innovative variable spacing, these concaves are built to withstand challenging harvest conditions, reducing stress on your combine and extending the lifespan of both the concaves and your equipment. Let’s dive into what makes these concaves a long-term investment and how they contribute to machine longevity.

Why do I not need to run cover plates in the Razors Edge?

The elimination of cover plates is possible thanks to the advanced engineering behind the Razors Edge Concaves. Traditional concave systems often require cover plates to control the flow of material and adjust threshing intensity based on the crop being harvested. These plates block off sections of the concave to increase threshing force or slow down material flow, depending on the crop. While effective, cover plates add an extra step to the harvest process and require constant adjustment as crop conditions change.

» Read more about: Why do I not need to run cover plates in the Razors Edge? »

What makes the Razors Edge the best Concave on the market?

The Razors Edge Concaves have quickly established themselves as a top-tier solution for farmers looking to maximize efficiency and performance during harvest. From their innovative design to their versatile functionality, the Razors Edge Concaves offer numerous advantages over traditional concave systems, making them the best concaves on the market. Let’s talk about why they stand out.

» Read more about: What makes the Razors Edge the best Concave on the market? »

How Laser-Clad Notched Bars Enhance Threshing in Tough Conditions

The laser-cladding process creates an extremely hard, durable, and sharp edge that maintains its integrity and sharpness far longer than conventional materials. The key benefit of laser cladding is its precision and durability. The process allows for very specific sharpening of the notched edge, ensuring it performs at peak efficiency in the most demanding conditions.

» Read more about: How Laser-Clad Notched Bars Enhance Threshing in Tough Conditions »

What Crops Have Shown Significant Improvements In Performance With The Razors Edge Concaves?

The Razors Edge Concaves by Thunderstruck Ag Equipment have been rigorously tested across a variety of crops in field trials, showing exceptional improvements in both performance and efficiency. Designed with an innovative variable spacing system, these concaves have proven their versatility and ability to handle multiple crops without the need for additional adjustments, such as cover plates. Let’s take a closer look at the specific crops that have shown significant improvements during field trials with the Razors Edge Concaves.

Do I need to run cover plates with the Razors Edge Concaves?

Short answer: No!

Long answer: No, you don’t need to run cover plates with the Razors Edge Concaves, this feature is one of the standout advantages of this innovative product. Cover plates have traditionally been a necessary component of conventional concave systems, used to fine-tune threshing intensity for different crops. However, they often add an extra layer of complexity to harvesting, requiring installation, adjustment, and removal depending on crop types and conditions.

» Read more about: Do I need to run cover plates with the Razors Edge Concaves? »