Blog Category: i-paddock

When you invest in harvest equipment, you’re not just buying parts, you’re buying uptime, efficiency, and peace of mind. The i-paddock Typhoon drum was engineered with exactly that philosophy: eliminate bottlenecks, increase capacity, and keep you running through the toughest crop conditions. But one of the most common questions farmers ask is: How long will the Typhoon last?

When you’re running a mixed operation, you need equipment that handles whatever you put in front of it. The i-paddock Typhoon drum was built exactly for that, consistent feeding, aggressive grab, and smooth, even flow through the combine. While it performs in almost any crop, farmers see the biggest benefits in canola, soybeans, lupins, and barley.

» Read more about: What Crops Is the Typhoon Best Suited For? »

You hit a patch of green or damp crop and suddenly the header starts to fight you. Material bunches, wraps, or plugs, and the combine slows to a crawl. These are the moments that separate an average feeding drum from one built to handle tough conditions. The Typhoon is the feeding drum for green or damp crops.

» Read more about: How Does the Typhoon Handle Green or Wet Crops? »

Does Ground Speed Change Between Sizes of Headers?

Not always. Many operators wonder, does header size affect ground speed, but moving up to a bigger header doesn’t mean you have to crawl. In reality, your ground speed has far more to do with what’s coming through the machine than how wide your header is.

» Read more about: Does Ground Speed Change Between Sizes of Headers? »

When it comes to harvest gear, durability isn’t a nice-to-have, it’s nonnegotiable. The Typhoon Feed Drum was built by an Australian farmer who was sick of fixing parts when we should’ve been harvesting. So he designed a feed drum that lasts.

The Typhoon drum’s patented paddle flighting and aggressive finger design deliver exceptional Typhoon drum feeding performance, keeping crops moving in a continuous, even stream. By smoothing feed into the feederhouse, operators can maintain higher ground speeds with fewer slowdowns. In canola and legumes, that feeding performance often translates into a gain of 2 to 4 kilometers per hour when conditions allow.

Why speed goes up

Ground speed is limited by how steadily the header and feederhouse can deliver the crop.

» Read more about: Does the Typhoon Really Help Me Harvest Faster? »

When it comes to feeding performance, not all drums are created equal. Most lock you into a single finger position with no real way to adjust for different crops or conditions. That’s where the Typhoon feeder drum breaks the mold.

» Read more about: How the Typhoon’s Quick-Adjust Feature Gives You Total Feeding Control »

If you’re looking at the i-paddock Typhoon to boost your spreading performance, one of the first questions that probably comes to mind is: is the Typhoon compatible with my header? You’re not alone, compatibility is one of the most common questions we get from farmers across North America.

The good news? We built the Typhoon with compatibility in mind, especially for the headers that farmers rely on most.

» Read more about: Is the Typhoon Compatible With My Header? »

If you’ve ever fought with uneven crop flow or frustrating feed delays during harvest, chances are your OEM drum is part of the problem. Factory-standard finger drums often don’t cut it, especially in tough conditions or when you’re pushing hard to beat the weather. You need a combine drum upgrade for better crop feeding.

» Read more about: More Fingers, Better Feed: What Makes the Typhoon Stand Out »

When it comes to upgrading your harvest performance, downtime is the last thing you want. That’s why the i-paddock Typhoon is designed with simplicity and speed in mind—so you can get it installed and back in the field without losing a valuable harvest window.

» Read more about: Fast & Simple: Installing the i-paddock Typhoon »

When you’re in the thick of harvest, everything comes down to how efficiently your machine can move crop through the front. Slowdowns, blockages, and slugging don’t just cost time—they cost yield. That’s why even small design changes, like drum diameter, can make a massive difference.

» Read more about: How a Smaller Diameter Drum Improves Harvest Flow »

It’s a good question—and one we hear often: “If the i-paddock Typhoon doesn’t have a reversing clutch, how do I back it out when it plugs?”

The answer? You reverse it just like you would any OEM header drum—using your combine’s standard reversing procedure. No special tools, no unique setup. It’s that simple.

» Read more about: How Do You Reverse the Typhoon Without a Reversing Clutch? »

Let’s talk about the part of your harvest that might be holding you back.

If you’re dealing with uneven crop flow,, or frustrating blockages at the front of your header, you’re not alone. A lot of farmers wrestle with feeding issues—especially in bulky crops, short crops, or tough conditions. The good news? There’s a simple upgrade that can make a big difference.

» Read more about: How Can I Improve the Feeding of My Header? »

Harvest season is always a busy time, and when you’re out in the field, every minute counts. But nothing throws a wrench in your plans quite like unexpected delays. One of the most frustrating culprits? Chain slippage on your header’s feed drum. If you’ve been there, you know how quickly it can bring your operation to a halt, leaving you scrambling to get things back on track.

» Read more about: Tired of Chain Slippage Causing Harvest Delays? There’s a Simple Solution »

Overcoming Header Feeding Challenges: How the Right Drum Can Make All the Difference for Your MacDon Header

Harvest season is a critical time, and if you’re running a MacDon header or a Case IH harvester, you know every minute counts. However, dealing with delays caused by issues with your header’s drum can quickly turn a smooth operation into a series of frustrating setbacks. Uneven feeding, crop compression, and frequent plugging are common challenges that many operators face. Let’s explore why these problems occur and how upgrading your drum can lead to a more efficient harvest.

One of the biggest issues facing farmers at harvest is the limited capacity that they encounter with their draper header feed drum. As OEM header drums force material towards the center of the drum and only feed through at the center of the drum, this limits the capacity to feed crops into the combine,and ultimately reduces the capacity of the header. In addition farmers run the risk of plugging their machine, as well as increasing rotor loss as often the material will clump when feeding with the OEM drums.

» Read more about: Increase Combine Header Feeding Drum Capacity – Thunderstruck Ag »

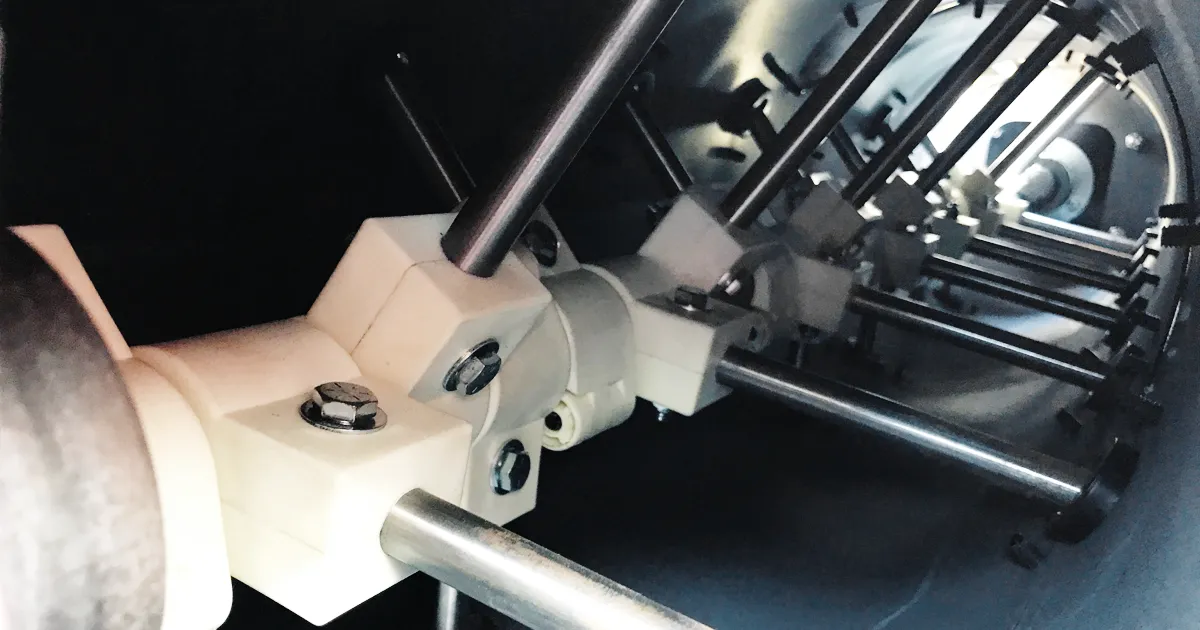

The iPaddock Typhoon™ was designed to maximize capacity and minimize downtime. This heavy-duty feed drum is designed with strength and adaptability. It is one of the highest and most efficient combine harvest equipment in the market.

The iPaddock Typhoon™ grabs crops and pulls it through in a continuous even flow, allowing you to go faster and get the crop off fast.

The iPaddock Twister™ chain tensioner is the latest product from iPaddock (a management system farm based in the south east of Western Australia founded in 1992). This chain tensioner solution fixes the problem of the drive chain coming off the feed drum on the Macdon fronts. It has a slot that is cam shaped that makes precise adjustment of chain tension possible with just manual pressure, while preventing the tensioner from sliding loose in the way when it is tightened up again.